"Agrajag" (Agrajag)

"Agrajag" (Agrajag)

12/31/2013 at 08:42 • Filed to: status:mended

1

1

5

5

"Agrajag" (Agrajag)

"Agrajag" (Agrajag)

12/31/2013 at 08:42 • Filed to: status:mended |  1 1

|  5 5 |

Helped my older brother change driver side wheel bearing and lower ball joint on his car.(more inside)

His 2005 Civic he's had since new was making the telltale failed wheel bearing noise. Having never attempted anything like this we figured why the hell not. We have repair manuals, tools and the internet, we can do this. And we did, just not with the same ease that everyone else seems to enjoy.

Everything was coming apart easily except for the lower ball joint. It would not budge from it's position in the control arm. We tried reattaching to the strut, hitting it with a hammer, prying, and every combination those two can provide. Finally, conceding, we bought the correct tool for the job.

Yes that's broken. But we got the ball joint separated from the control arm. It was apparent we would need a new ball joint right away as the boot tore immediately. But upon tightening the tool, it was still not budging. My brother manning the wrench says, "did it work? It just got really easy to tur.....the head broke. Fuck."

me: "Fuck."

Now we had the tool stuck on there. To me, my hammer. THWACK!!! KAPING!!!! It goes flying, and luckily the ball joint dislodges itself from the control arm.

We head to AutoZone to get the ball joint press/removal tool. We had to cut some of the threads off so it fit correctly inside the tool, since we hadn't gotten the adapter kit you should get as well. Once we figured that out, it was easy.

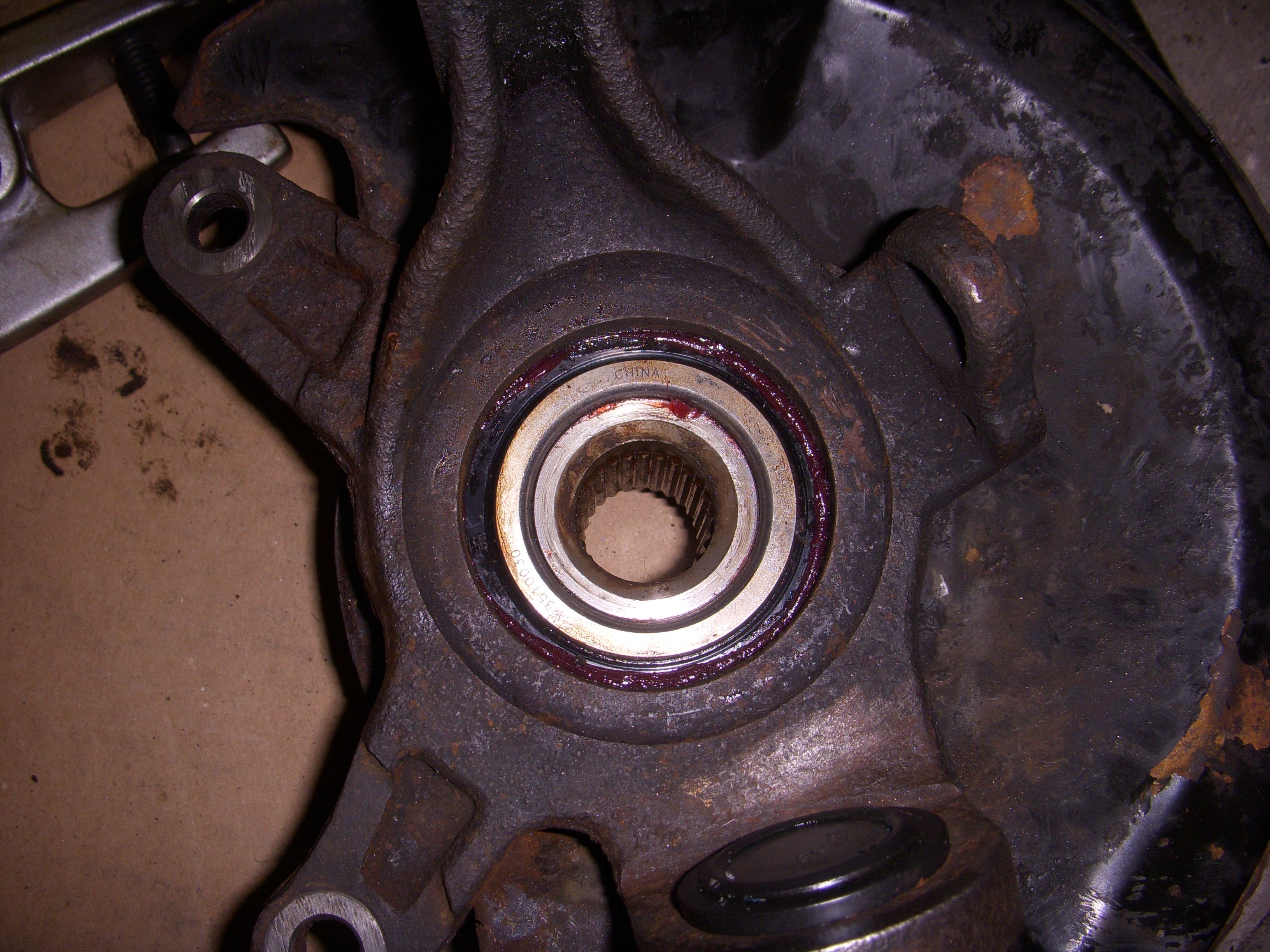

Finally removed.

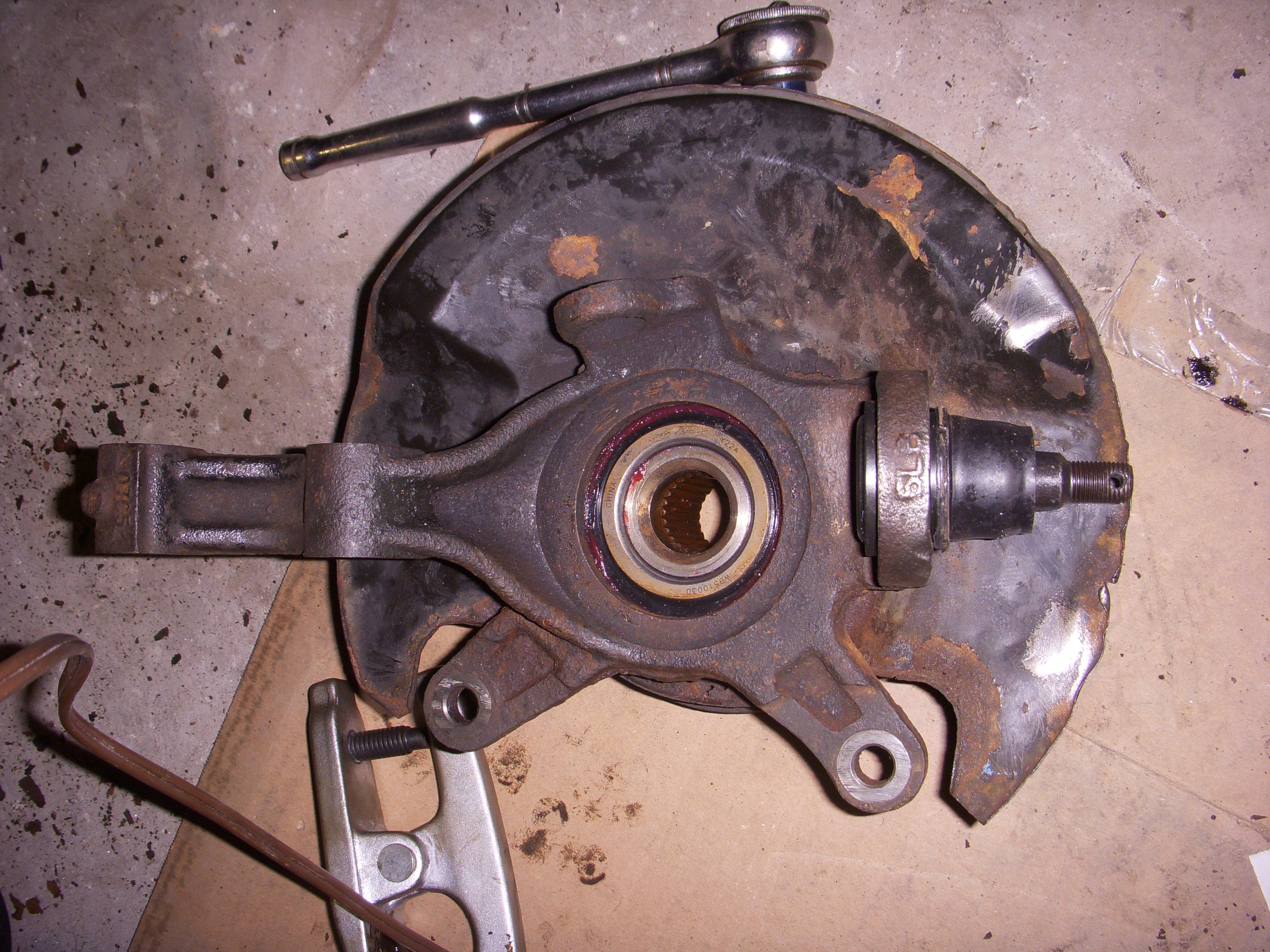

The work space.

Having not much time left I contacted the shop I use for my cars, and they were awesome enough to remove and press in the new bearing. Thankful beyond measure for that.

We also replaced the front brake pads since they were near the end of their life. All in a good time. He made the 2 hour journey home with no issues. Learned some new stuff and added to my tool collection. Finally got a torque wrench, and hopefully I can get a new bolt for that ball joint tool.

rabidpenguin

> Agrajag

rabidpenguin

> Agrajag

12/31/2013 at 09:38 |

|

Nice work, this is how it starts. The more you do, the more confidence you get working on the car and the ability to tackle bigger jobs. That is how it worked for me at least.

That ball joint removal tool has worked pretty well for me, but you need to make sure you grease(never seize or wheel bearing) the bolt that you snapped. You can also use a pickle fork and a hammer if you don't care about ripping the boot to shreds. In some cases you may also get the ball joint to release if you hit the side of the collar that the ball joint stud goes through.

Agrajag

> rabidpenguin

Agrajag

> rabidpenguin

12/31/2013 at 12:12 |

|

Thanks. We tried hitting the collar but to no avail. I just went and got another one of those tools, so I'll make sure to grease that one, as we'll have to do the lower ball joint on the other side soon.

rabidpenguin

> Agrajag

rabidpenguin

> Agrajag

12/31/2013 at 12:17 |

|

I am still surprised it broke though. I even use the impact gun on mine and haven't had any trouble.

Agrajag

> rabidpenguin

Agrajag

> rabidpenguin

12/31/2013 at 12:59 |

|

Maybe it was defective, we were just using a 1/2" drive socket wrench. Didn't even use the cheater bar.

Mercwri

> Agrajag

Mercwri

> Agrajag

01/10/2014 at 23:38 |

|

I almost never used any thing other than a hammer and prybar to get a ball joint free from a control arm.

The trick is to have someone apply pressure on the arm with the pry bar while you hit around with a large hammer (5lb or more). Slow, HARD, hits and try not to let the hammer bounce around, hit it like you are trying to bury the hammer through to the other side.

Failing that an Air Chisel with a flat head on it and abuse the control arm around the stud, then switch to one with a blunted point and press hard while giving it a quick blast.

If that doesn't work its frozen in and now has become one, cut it the fuck out and then press the remains of the stud out with a ball joint press.